Recon tobacco sheets represent a fascinating intersection of tradition and innovation within the tobacco industry. These sheets are not just a product but a testament to the ingenuity of tobacco craftsmanship. By transforming tobacco byproducts into a valuable commodity, Recon tobacco sheets challenge the conventional perception of tobacco processing and utilization. They embody a synergy of science and artistry, where every sheet is a narrative of transformation from discarded elements to a crucial component in the smoking experience. This blog post peels back the layers of this enigmatic material, exploring its creation, its role in the industry, and its potential to shape the future of tobacco consumption.

The Science Behind Recon Tobacco Sheets

Recon tobacco sheets are a product of scientific innovation. They are made from tobacco byproducts, which are transformed into a valuable commodity through a unique process. This process involves the use of heat and pressure to create sheets that are similar in texture and flavor to traditional tobacco leaves.

The Process of Making Recon Tobacco Sheets

The creation of Recon tobacco sheets is a meticulous process. It begins with the collection of tobacco byproducts, which are then cleaned and processed. These byproducts are then subjected to heat and pressure, transforming them into sheets that can be used in the same way as traditional tobacco leaves.

The Role of Recon Tobacco Sheets in the Tobacco Industry

Recon tobacco sheets have a significant role in the tobacco industry. They provide a sustainable and cost-effective alternative to traditional tobacco leaves, which are becoming increasingly scarce due to environmental and economic factors.

The Impact on Cigarette Manufacturing

Recon tobacco sheets have revolutionized cigarette manufacturing. They allow for a more efficient and cost-effective production process, as they can be cut to precise sizes and shapes. This has resulted in a significant reduction in waste and an increase in productivity.

The Economic Implications

The economic implications of Recon tobacco sheets are profound. They have the potential to significantly reduce the cost of cigarette production, which could lead to lower prices for consumers and higher profit margins for manufacturers.

The Quality and Characteristics of Recon Tobacco Sheets

Recon tobacco sheets are known for their high quality and unique characteristics. They have a similar texture and flavor to traditional tobacco leaves, making them a popular choice among manufacturers and consumers alike.

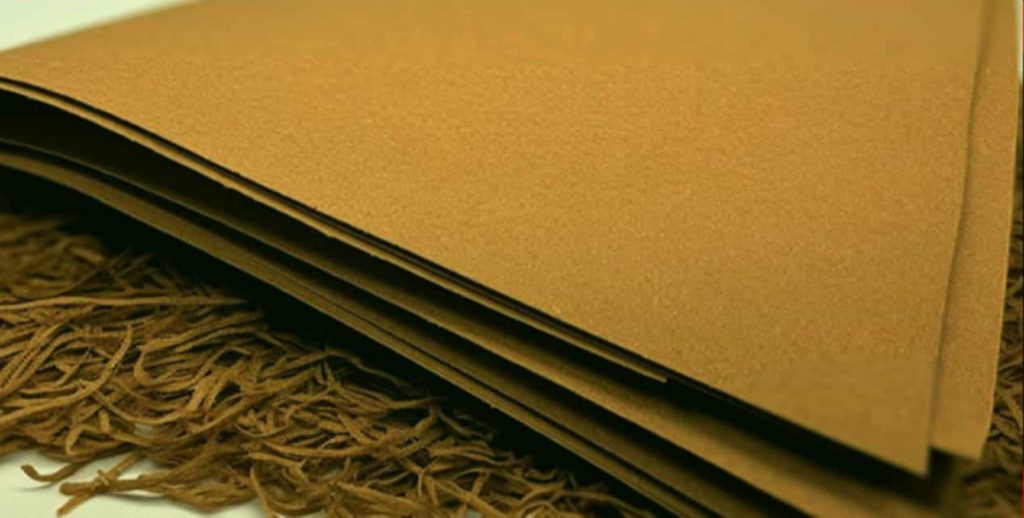

Texture and Composition

The texture and composition of Recon tobacco sheets are similar to that of traditional tobacco leaves. They are smooth and flexible, making them easy to work with during the manufacturing process.

Flavor Profile

The flavor profile of Recon tobacco sheets is comparable to that of traditional tobacco leaves. They provide a rich and satisfying smoking experience, which is highly valued by consumers.

The Future of Recon Tobacco Sheets

The future of Recon tobacco sheets looks promising. With advancements in technology and changing market trends, they are set to play an even more significant role in the tobacco industry.

Technological Advancements

Technological advancements are likely to further improve the quality and efficiency of Recon tobacco sheets. This could lead to even better products and more cost-effective production processes.

Potential Market Trends

As consumers become more aware of the benefits of Recon tobacco sheets, their demand is likely to increase. This could lead to a significant expansion of the market and a greater role for Recon tobacco sheets in the tobacco industry.

what is the history of reconstituted tobacco sheets

The concept of reconstituted tobacco, also known as recon tobacco sheets, dates back to the early 20th century . However, the significant development of reconstituted tobacco started in the 1970s with the introduction of Paper Based Technology developed by Kimberley Clark . This technology allowed for the transformation of tobacco byproducts into a new, reconstituted form that could be used in various tobacco products .

In the 1990s, a new production process for reconstituted tobacco was launched called Slurry RECON by China National Tobacco . This process involved creating a slurry from tobacco particles and binder, spreading it into sheets, and then drying and cutting the sheets to size .

In the early 2000s, a hybrid of Paper Process and Slurry was developed by companies such as BAT . This method combined the best aspects of both processes to create a more efficient and high-quality product .

The latest technology developed in 2008 was Nano Fiber RECON . This technology, pioneered by RECON INC Brazil and commercialized by STI, has become the benchmark for the best quality Reconstituted Tobacco in the world due to its aromatic preservation, filling power, and cost efficiency .

Over the decades, the evolution of reconstituted tobacco has been remarkable, with the integration of components like cloves and hemp, leading to the creation of novel products . The primary objective of reconstituted tobacco has always been the optimal utilization of tobacco materials, ensuring no wastage .

how do reconstituted tobacco sheets affect the taste and quality of cigarettes

Reconstituted tobacco sheets, or recon tobacco sheets, can significantly affect the taste and quality of cigarettes. These sheets are made from tobacco byproducts such as dust, stems, and scraps, which are combined with a binder to form sheets that can be used as cigarette filler .

The use of recon tobacco sheets in cigarette production has several benefits. They provide consistency in cigarette production and can reduce the nicotine and tar content in cigarettes, making them a potentially healthier option for smokers .

Recon tobacco sheets can also affect the taste of tobacco products and the quality of cigarette products . The taste of a cigarette can be influenced by the type of tobacco used, the size of the tobacco scrap, and the specific process used to create the recon tobacco sheets .

Moreover, the use of additives in the production of recon tobacco sheets can also influence the taste and quality of cigarettes. For instance, additives that produce flavors are added to tobacco to improve the taste of smoke, either by introducing pleasant flavor notes or by masking unpleasant ones .

Conclusion

Recon tobacco sheets represent a significant innovation in the tobacco industry. They provide a sustainable and cost-effective alternative to traditional tobacco leaves, without compromising on quality or flavor. With advancements in technology and changing market trends, they are set to play an even more significant role in the future of the tobacco industry.

FAQs:

What is the future outlook for Recon tobacco sheets?

The future outlook for recon tobacco sheets is promising, with technological advancements likely to improve their quality and efficiency, potentially leading to a larger market share within the tobacco industry .

What are the key differences between Recon tobacco sheets and traditional tobacco leaves?

Recon tobacco sheets are made from tobacco byproducts and a binder, while traditional tobacco leaves are whole, unprocessed leaves. Recon sheets can be engineered to have controlled properties such as porosity and moisture content, which are not as easily controlled in whole leaves .

What are the advancements in Recon tobacco sheet technology?

Advancements in recon tobacco sheet technology include the development of new production methods such as tobacco dough casting and air-laid recon, as well as the use of nanofiber technology to enhance the sensory attributes of the sheets .

What are the challenges in producing Recon tobacco sheets?

Challenges in producing recon tobacco sheets include maintaining uniform thickness and quality, ensuring the sheets can withstand the manufacturing process without breaking, and replicating the sensory characteristics of traditional tobacco leaves .

What are the cost-effective aspects of Recon tobacco sheets?

Recon tobacco sheets are cost-effective because they utilize tobacco byproducts, reduce waste in cigarette manufacturing, and can be produced with less variability in quality, leading to more efficient production processes .

What are the traditional methods of producing Recon tobacco sheets?

Traditional methods of producing recon tobacco sheets involve creating a slurry from tobacco particles and binder, spreading it into sheets, and then drying and cutting the sheets to size .

What are the physical properties and thermal behavior of Recon tobacco sheets?

Recon tobacco sheets have controlled porosity, moisture content, and combustion characteristics, which can be tailored to specific requirements for cigarette manufacturing. They are designed to provide even and efficient heating.

How do Recon tobacco sheets impact cigarette manufacturing?

Recon tobacco sheets impact cigarette manufacturing by allowing for more precise control over the properties of the smoking material, leading to more consistent products and potentially reducing the formation of harmful compounds.

What are the quality and characteristics of Recon tobacco sheets?

The quality and characteristics of recon tobacco sheets include their uniform appearance, strength, elasticity, and the ability to replicate the flavor profile of traditional tobacco leaves .

What are the potential market trends for Recon tobacco sheets?

Potential market trends for recon tobacco sheets include increased demand as consumers seek alternatives to traditional smoking products and as manufacturers look for more cost-effective and sustainable materials .

What are the economic implications of Recon tobacco sheets?

The economic implications include the potential for reduced production costs for cigarette manufacturers, which could lead to lower prices for consumers and higher profit margins for the industry .

What is the role of Recon tobacco sheets in the tobacco industry?

Recon tobacco sheets serve as a sustainable alternative to whole leaf tobacco, providing a use for byproducts and contributing to more efficient manufacturing processes .

What are Recon tobacco sheets made from?

Recon tobacco sheets are made from tobacco byproducts such as dust, stems, and scraps, combined with a binder .

How are Recon tobacco sheets produced?

Recon tobacco sheets are produced by creating a slurry from tobacco byproducts and binder, forming the slurry into sheets, drying the sheets, and then cutting them to the desired size for use in smoking products .

Sources of information:

Sources of information on recon tobacco sheets include patents and technical documents that describe the manufacturing processes, properties, and applications of these materials https://patents.google.com/patent/US5724998A/en

https://patents.google.com/patent/US20080006286A1/pt

https://patentimages.storage.googleapis.com/b4/87/6c/9f51a4395a7490/EP0565360A2.pdf

https://www.ashland.com/file_source/Ashland/Documents/TIB_VC-701B_Reconstituted_Tobacco_Sheets.pdf

https://www.tobaccoasia.com/news/no-outdated-technologies-for-htp-recon-tobacco/

https://patents.google.com/patent/WO2015197553A1/ja

https://patents.google.com/patent/EP2134203B1/en.

Citations:

Authoritative sources on the subject of recon tobacco sheets can be found in patents and scientific articles that detail the methods of production, the properties of the sheets, and their role in the tobacco industry https://patents.google.com/patent/US5724998A/en

https://patents.google.com/patent/US20080006286A1/pt

https://patentimages.storage.googleapis.com/b4/87/6c/9f51a4395a7490/EP0565360A2.pdf

https://www.sciencedirect.com/science/article/abs/pii/S0926669014003355

https://www.ashland.com/file_source/Ashland/Documents/TIB_VC-701B_Reconstituted_Tobacco_Sheets.pdf

https://www.tobaccoasia.com/news/no-outdated-technologies-for-htp-recon-tobacco/

https://patents.google.com/patent/WO2015197553A1/ja

https://patents.google.com/patent/EP2134203B1/en

https://www.researchgate.net/publication/315850162_Physical_properties_and_thermal_behavior_of_reconstituted_tobacco_sheet_with_precipitated_calcium_carbonate_added_in_the_coating_process.